|

Hi. My name is Mike, but most

people around the customizing community might recognize my online persona of

minesurfer. My custom action figures debuted at

Custom Con 9 (Fall 2003) on Joe Acevedo’s page. They are the Legion of

Superheroes figures that had a submission on each day. Enough about me though…

Waisting Away

Have you ever looked at the Blink figure that was part of Toy Biz’s Marvel’s

Most Wanted line and thought, “This is a really nice female base figure, but

the legs look like she is suppressing the urge to relieve some bodily

pressures? I can’t use this.” If you have thought this or something close to

it, then this article is for you. I will be taking you through the steps I

used to join the torso from one figure to the legs of another figure.

The base figures you want to combine are important because they will dictate

what you have to create. What you want to do is try to choose at least one

figure that is already articulated at the waist. Hopefully the figures you

choose will have a “male” peg on the part that you want to use, so all you

have to do is create the “female” piece of the joint on the other figure. This

doesn’t have to be the case though as you can create male pegs with 2-part

epoxy clays and join just about any torso to any set of bipedal legs.

Unfortunately you won’t know what you have to work with until you get into the

cutting and dremelling. The thing you really need to pay attention to is where

you cut the torso that you intend to use. You want your custom to look

natural, so the lines of the torso should be an extension of the lines of the

legs or vice versa.

One other customizing skill you will need for this operation is disassembling

a figure. Here’s a brief overview of that process. Boil and pop the head. Use

a knife to cut the side and shoulder seams of the torso. Insert small needle

nose pliers in the neck hole and pry figure apart. See other articles and faqs

for more detailed descriptions.

Like any other task, you have to start somewhere. Here you see the two figures

to be joined at the hips. I like the Magik figure because the torso unscrews

in the back for easy disassembly. What you’re left with is fairly generic,

booted legs with a “male” peg at the top. The Rogue figure is a decent torso

because it’s cheap, easy to crack open without major damage, and it’s

relatively simple to discard of unwanted details (jacket sleeves and glove

cuffs). Here you see two original figures in the background, and in the

foreground you see the pieces that I will fit together from each original

figure.

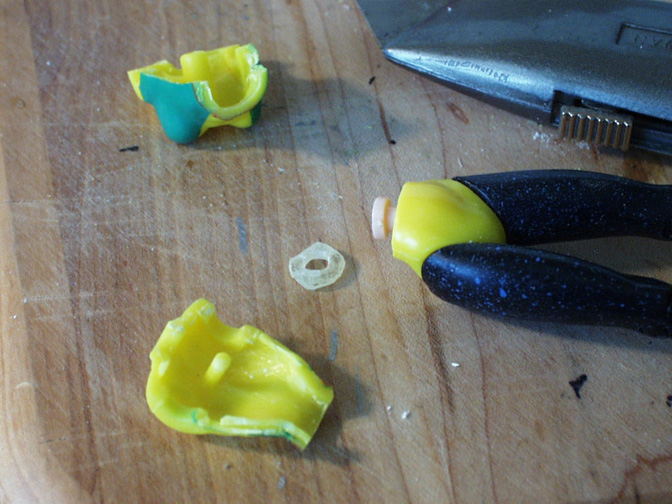

Find/make a piece of cured epoxy that is about the correct thickness. The

correct thickness is one that fits snugly between the horizontal piece of the

male peg and the lower abdomen area of the Magik figure.

A little bit about liquid epoxies

I don’t know why I don’t hear or read more about liquid epoxy as it pertains

to customizing. I’m sure other people are using it, but I just never hear

about it. Sure I’ve read where a lot of customizers use 2-part epoxy

clays/putties (Kneadatite, plumber’s epoxy, etc.) for sculpting and the like.

That’s not what I am talking about here. If you are not familiar with the

liquid epoxies, I highly recommend you become familiar with them. When I first

started customizing I was trying to combine pieces with super glue. Super glue

is by far the inferior product to epoxy when used for the purpose of combining

plastic pieces into one, stable, permanent unit. Try liquid epoxy for yourself

if you haven’t already. You can find it cheap (around $2 to $5 per package) at

Target, Wal-Mart, Meijer, Home Depot, Lowes, etc.

Now… I’m not technically savvy about epoxy, but from my experience it is two

relatively viscous liquids that when combined in the appropriate ratio

(usually a 1:1 which is easy to achieve because most epoxies come in dual

plunger packaging), create a chemical reaction that produces a hard,

plastic-like material. The great part about this is that it usually (depending

on the properties of the epoxy and what it is designed to stick or not stick

to) sticks to plastic and forms a bond that is as strong as the original

plastic, if not stronger. In my experience it is a little harder to cut with a

utility knife than most action figure pieces, but when it is cured it is

easily sandable for nice, smooth surfaces. It is not odorless though, but what

odor is present is not overpowering or unpleasant.

Now, there are all types of epoxies out there so you may have to experiment

with different types to find what works best for you. Some set in 90 seconds,

while others take over an hour. Some are a little runnier than others which

can make assembly a little tricky. You can find some epoxies that are strong

enough for construction purposes and others that are specifically designed for

marine usage/repairs. Always read the label before you purchase the epoxy to

make sure it applies to your use and time needs.

The one drawback to liquid epoxies, and it is a small one to me, is that when

you are mixing it, you will always have a little waste left over. That is the

nature of the dual plunger package, but that also leads to materials that can

be used for customizing. I usually just mix the liquid epoxy in the “bubble”

it was packaged in or if I want a bigger mixing space, I mix it in an action

figure’s bubble that has been separated from its card. Once the epoxy is

cured, you can just pop it from the “bubble” with pressure from below.

Cut the cured epoxy to the approximate shape needed with a utility knife. I

place the action figure piece on top of the epoxy and score the cut first

based on the rough outline of the piece. Exacto knives will work too, but

utility knives allow you to apply more pressure and will accomplish the task

better.

Once your cured epoxy is cut into a basic shape, you have to start the fine

tuning its shape with a dremel (or any appropriate rotary tool). I like the

metal cutting bits over the grinding, stone bits. The metal tips will have a

straight, smooth cutting surface that will leave a more refined edge on your

cured epoxy. Also the metal tip is better for drilling holes if you decide to

go that way later. Use what you feel comfortable with. I also recommend using

a dremel stand to hold your dremel. This will allow you to use both hands to

steady your piece and bring it to the tool instead of having to control both

the piece and the tool at the same time. I think I bought my stand at Home

Depot a few years back for about $50 and I haven’t regretted it once.

Continue refining the shape of the cured epoxy until it fits inside the torso

of the Rogue figure at the location where you want it to be. Be careful to

support and control the positioning of the epoxy near the dremel bit. If you

don’t have good control, the bit will send the cured epoxy flying.

Dry fit the cured epoxy to make sure that the torso actually closes with the

cured epoxy in place. Keep refining the shape until you are satisfied with the

fit and the closure of the torso.

Whip out the ole utility knife again and cut the cured epoxy to coincide with

the side seams of the torso. If you are so inclined, you could drill a hole in

the middle before you cut, but I still recommend shaping the hole after the

cut.

Back to the dremel… Shape the epoxy so that it fits the vertical shaft of the

male peg. <aside> Minds out of the gutters please. </aside>

Permanently affix the epoxy to the torso where you dry fit it before. I

recommend doing this with more epoxy. After the epoxy cures, you may have to

do some more fine-tuning with the dremel. This will be in order to make sure

the top of the male peg is not conflicting with the epoxy that you used to

join the original cured epoxy to the plastic torso. I tend to shape the epoxy

so that the peg fits around it, but I have, on occasion, modified a peg or two

to fit around the epoxy.

The final step is to reattach the two pieces of the torso. I have done this in

several ways. The cost effective way is to use liquid epoxy, but this is also

the messiest. Not only that but if the mess spreads beyond your control (or

notice), then you are likely going to loose some articulation. Recently I

picked up some liquid epoxy for marine purposes, and when you mix it, it does

not flow like regular liquid epoxies. I think I am going to start using the

marine epoxy for future assembly projects.

You can weld the pieces back together with a soldering iron, but this is going

to leave some clean up sanding and filing to do. Not to mention soldering

irons are hot and dangerous.

The easiest and safest way to join the figures back together is to put some

Kneadatite (or other two part epoxy putty) on the seams and let it cure. The

draw back to this method (for me anyway) is that epoxy clays like Kneadatite

can be expensive (usually around $12.00/tube) and hard to acquire. If you can

find a cheap, quick curing, two-part epoxy putty, then this is the way to go.

You can find the cheaper sculpting epoxies (seen here) in the plumbing

sections at Home Depot, Lowes, and other stores of that type; usually it costs

around $6.00 (US) for a tube. Don’t think that the plumber’s epoxy putty will

replace Kneadatite as an all around sculpting material though, as it has a

considerably less amount of curing time (anywhere from 2 to 20 minutes vs. 1

to 1.5 hrs for Kneadatite).

Here’s the finished product along with the tools and safety equipment you need

to make it happen. Here you can see the liquid epoxy in its dual plunger

package.

Public Safety Announcement: Always use safety glasses when operating dremels

during customizing activities. And when sanding, dust masks are a good thing

to wear too.

Now you can finish the rest of your custom.

Durability

So far I have used this technique or a variation of it on six figures and not

one of them has failed yet. Three of them will be on the web in the near

future, but you can see the other three customs in my Legion of Super-heroes

submissions in

Custom Con 9. (www.joeacevedo.com)

Supergirl (in Monday’s Legion submission), Umbra (in Wednesday’s Legion

submission), and Lightning Lord (in Friday’s Legion submission) were all put

together using this or a variation of this technique.

The process definitely has some durability when performed correctly. The first

custom I assembled using this technique was Umbra in the winter of 2002. Umbra

has fallen (the result of a domino effect started by other figures) from a

height of about 6 feet on more than three occasions. She has bounced off of

hardwood dressers on her way to the floor, with no damage to the joint. As

with most customs, I recommend light handling of the figure, but you don’t

have to be terribly gentle with it because of the waist joint. As long as the

materials you used are 2-part epoxies that were mixed in the correct ratios,

you shouldn’t have any strength problems.

Conclusion

This technique is not rocket science, and you may have to adjust it to fit

your needs. For example, if you are going to join a Marvel’s Most Wanted Blink

torso with the left over legs from the Rogue we just used, you will have to

make the female part of the joint for the Rogue legs because the Blink torso

has the male part of the joint. If neither piece has a male part then you can

make a peg out of kneadatite or some other two part epoxy clay material. The

good thing about this technique is if you are dissatisfied with the visual

results then you can cover the joint with belts (made from elastic) or fabric

skirts and still retain articulation. I don’t know about the applicability of

this technique to the Marvel Legends scale as I have not yet moved on from the

5” scale. I hesitate to speculate because I haven’t torn one of those figures

apart yet, but I would think that this technique should have some uses in

scales larger than the 5” scale.

Final Word: This technique will allow you to join the torso from just about

any figure with the legs from just about any other figure in a sturdy manner.

The technique itself is simple and uses strong, cheap, and readily available

materials to accomplish the intended goal.

Comments, questions, or suggestions will be appreciated, read, and/or answered

on the RTM forum, as I frequent the board often. If you feel the need to email

me, you can do so at [email protected].

Mike - minesurfer

|