Step

Eleven: Works Like & Looks Like Models –

Once these works like and looks like models are ready

from the factory they are sent to the account team for

review by both the client and the licensor if necessary.

This will be the final approval stage prior to beginning

to tool for the project and any and all changes need to

happen at this stage. Once these have been reviewed and

approved by all parties they are returned to Hong Kong

so that the factory can begin to start tooling.

Step

Eleven: Works Like & Looks Like Models –

Once these works like and looks like models are ready

from the factory they are sent to the account team for

review by both the client and the licensor if necessary.

This will be the final approval stage prior to beginning

to tool for the project and any and all changes need to

happen at this stage. Once these have been reviewed and

approved by all parties they are returned to Hong Kong

so that the factory can begin to start tooling.

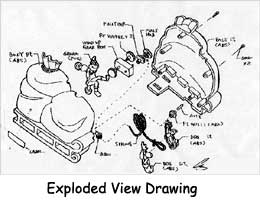

Step Twelve: View Drawings & Process Controls

– For most projects, you should request from the

factory that they provide Exploded  View

Drawings and Process Control Charts. What these two documents

are for is to show that the factory has understood exactly

what it is they are producing for you. With the exploded

view drawings, they are showing an engineering drawing

that details how each piece will be made an assembled.

With the process control chart, this is a guideline to

demonstrate all of the steps that will be used in the

manufacturing of the product. By having your engineers

and quality assurance staff review these documents you

can determine that the factory understands exactly what

you have asked them to produce and that it can be done.

View

Drawings and Process Control Charts. What these two documents

are for is to show that the factory has understood exactly

what it is they are producing for you. With the exploded

view drawings, they are showing an engineering drawing

that details how each piece will be made an assembled.

With the process control chart, this is a guideline to

demonstrate all of the steps that will be used in the

manufacturing of the product. By having your engineers

and quality assurance staff review these documents you

can determine that the factory understands exactly what

you have asked them to produce and that it can be done.

Step Thirteen: Inserts, Decals & Polybags –

At this stage you will need to receive from the creative

department all of the copy and artwork that is required

for the production of the inserts, decals or polybags

used on this project. This is usually provided in the

form of film or a disk. These will be sent to your Hong

Kong office who will review them and pass them along to

the factories. The factories will then provide proof sheets

on each item for review and approval by the client and

licensor if necessary prior to going into production.

Step

Fourteen: Tooling First Shots – The tooling is

now complete and we will begin to see “First shots”

(also known as “Test Shots”) out of the mold.

These are the first parts that are injected from the tool

and we evaluate them for size and function. These have

not been decorated yet and are not typically shared with

the client. It allows your engineers to see the parts

and make any adjustments if necessary to the tool prior

to going into production.

Step

Fourteen: Tooling First Shots – The tooling is

now complete and we will begin to see “First shots”

(also known as “Test Shots”) out of the mold.

These are the first parts that are injected from the tool

and we evaluate them for size and function. These have

not been decorated yet and are not typically shared with

the client. It allows your engineers to see the parts

and make any adjustments if necessary to the tool prior

to going into production.

Step Fifteen: Limit Set Samples and Meeting

– After the first shots have been reviewed and any

modifications have been made to the tool, a request is

made to the factory to provide pre-production samples.

These samples will be representative of the production

line product and will be used for a “limit set”

meeting with the client. At the limit set meeting these

samples will be reviewed for decoration, function and

safety to determine they are ready to proceed in to production.

Any changes or defects that occur at this stage have to

be taken care of prior to going in to production.