Step

Six: Engineering Drawings / QAP Request – Once

you have awarded the project you might have to send engineering

drawings that show how the item works or is constructed

to the testing lab that you are going to work with. Either

in-house engineers or ones at the favctory will supply these

drawings.

Step

Six: Engineering Drawings / QAP Request – Once

you have awarded the project you might have to send engineering

drawings that show how the item works or is constructed

to the testing lab that you are going to work with. Either

in-house engineers or ones at the favctory will supply these

drawings.

The criteria to determine how to test an item

will depend on the age grading of the item and how the product

is intended to be used. It is the responsibility of the

testing lab to evaluate your designs to make certain that

they can meet the requirements that you need for safety.

They will then make a Quality Assurance Plan (QAP) that

they will make certain your factories are following during

production.

Step Seven: QA Plan Sent To The Manufacturer

– Once the testing lab has provided an approved QAP,

this is then sent to the manufacturer as the guideline for

them to follow in producing the product. This QAP plan will

let the factory know what types of testing will take place

to make certain the product they are producing will be safe

and function properly in the environment it is intended

for. The QAP plan will also be followed closely by your

own Quality Assurance staff in Hong Kong to make certain

that the factory is conforming to everything in the QAP.

Step

Eight: Sculpts Sent To Hong Kong – Now that the

model maker has completed the sculpts and they have been

approved by the client and the licensor if necessary, they

are sent to the Hong Kong office to be given to the factory.

Depending on the product and license holder, approvals can

sometimes take multiple submissions, which should also be

factored into the timeline. At this time the factory will

make a duplicate model called a “looks like” model

and also a “works like” model which will show

the function that the product is supposed to do. These should

represent what the final product should look like and behave

like in the store. This is where you iron out most issues

in the design and make sure the factory is on the same page.

Step

Eight: Sculpts Sent To Hong Kong – Now that the

model maker has completed the sculpts and they have been

approved by the client and the licensor if necessary, they

are sent to the Hong Kong office to be given to the factory.

Depending on the product and license holder, approvals can

sometimes take multiple submissions, which should also be

factored into the timeline. At this time the factory will

make a duplicate model called a “looks like” model

and also a “works like” model which will show

the function that the product is supposed to do. These should

represent what the final product should look like and behave

like in the store. This is where you iron out most issues

in the design and make sure the factory is on the same page.

Step

Nine: Request Carton Markings – At this point the

account team needs to find out the information that the

client will require on the master cartons. This information

is required early in the production process due to the lead

time to produce the master cartons. Typically, each client

has certain specific information about the product and stocking

codes that they want printed on their master cartons. This

is also when you will begin to work on the creative and

copy for any inserts, decals and polybags required for the

project but not needed until later.

Step

Nine: Request Carton Markings – At this point the

account team needs to find out the information that the

client will require on the master cartons. This information

is required early in the production process due to the lead

time to produce the master cartons. Typically, each client

has certain specific information about the product and stocking

codes that they want printed on their master cartons. This

is also when you will begin to work on the creative and

copy for any inserts, decals and polybags required for the

project but not needed until later.

Step

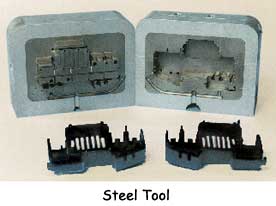

Ten: Legal Line Information – On every tool that

is made for the item you are manufacturing there needs to

be a client legal line included along with the country of

origin (ie) “Made In China”. This information

which may be the copyright logo along with the client logo

needs to be etched in the tool and is required prior to

the start of tooling. Once the tooling has begun this information

is difficult to change or add to and requires modifications

to the tooling. This is usually the last item added to the

tool. Tooling usually takes around 45 days, since the pattern

is being made by cutting into a block of steel then milled,

drilled, and polished.

Step

Ten: Legal Line Information – On every tool that

is made for the item you are manufacturing there needs to

be a client legal line included along with the country of

origin (ie) “Made In China”. This information

which may be the copyright logo along with the client logo

needs to be etched in the tool and is required prior to

the start of tooling. Once the tooling has begun this information

is difficult to change or add to and requires modifications

to the tooling. This is usually the last item added to the

tool. Tooling usually takes around 45 days, since the pattern

is being made by cutting into a block of steel then milled,

drilled, and polished.

.